Despite a challenging economic market across the UK, independent chocolate makers are embracing a bean-to-bar model, focusing on transparency, ethics, and incredible flavour. But while the appeal is growing, so too are the challenges.

While many of us like to indulge in chocolate over the Easter weekend, how about attempting to make your own bar of chocolate?

York Cocoa Works is running a highly successful Bean to Bar Masterclass, which I was invited to attend when I visited last month.

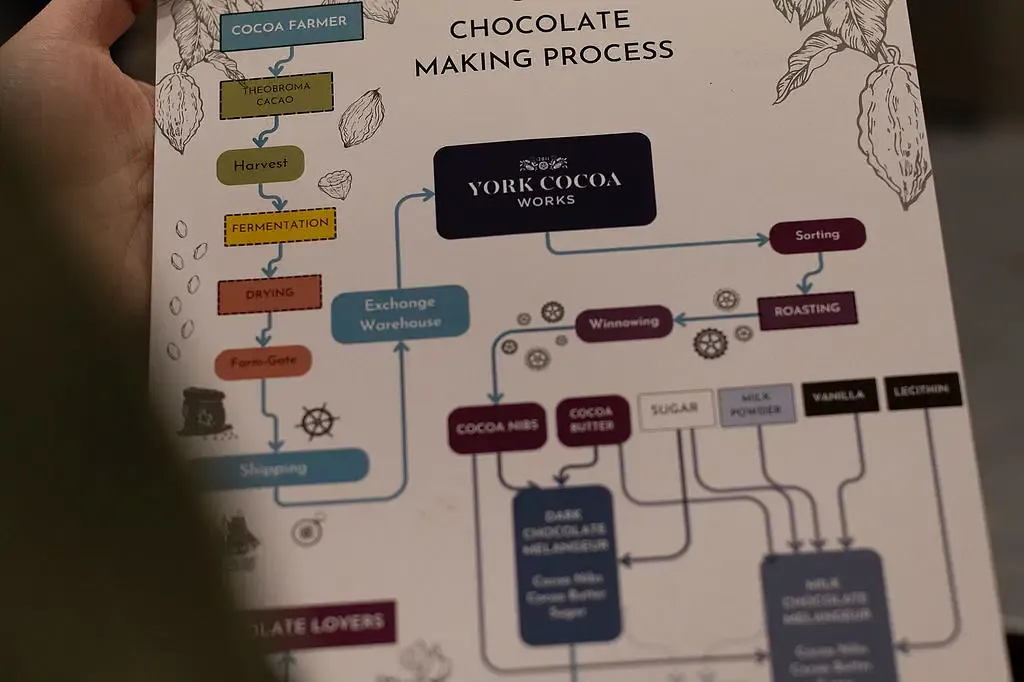

Sophie Jewett is the managing director at York Cocoa Works and also runs the academy. She says: “Our Bean to Bar Masterclass is our favourite workshop covering the full chocolate making process from cocoa bean to the finished chocolate product our participants took home as finished, tempered chocolate bars designed and crafted to their own recipe!

“Participants can choose their own cocoa origins or select their blend of beans from the origins and flavours we use in our chocolate. We explore and analyse cocoa beans based on variety, country, and fermentation before roasting the beans and then setting about the chocolate-making process.”

Meticulous explanations and preparations

The Masterclass begins outside the premises, and participants are given a short lesson on the origin of cocoa before moving inside to start making chocolate.

The class of 12 was taken through each process stage with meticulous explanations by Sophie from the roasting, winnowing, tempering, and melanger stages. The fact that you can create a chocolate bar in roughly half a day, replicating the procedures of the big chocolate makers like Nestlé and Cadbury, is a stroke of genius, and the use of hairdryers to heat the chocolate in the melanger was inspiring.

Some of the stages and processes in the York Cocoa Works Bean to Bar Masterclass. Images: York Cocoa Works

Sustainable cocoa

York Cocoa Works has many varieties of sustainable cocoa from countries of various origins. I used 65% Guatemalan cocoa (supplied by Uncommon Cacao) with 25% sugar and 10% cocoa butter in my chocolate bar.

The cocoa butter was also made on the premises because, as Sophie explains, the price is now exorbitantly high, leading some manufacturers to use substitutes like shea butter.

After the conching, the chocolate is tempered by hand before being put into moulds and then cooled in a fridge before being wrapped and ready to take home.

York Cocoa Works is part of a new era of chocolate makers, working directly with cocoa beans and growing communities to craft the chocolate on their own premises to share with the rest of the world.

The challenges of bean to bar chocolate

1. Higher Costs, Lower Margins

Craft chocolate is made in small batches with high-quality, often single-origin cacao beans. These beans are more expensive than bulk commodity cacao, and sourcing them ethically adds further cost. Combine that with small-scale production, hand-wrapping, and premium packaging — and margins can get razor-thin.

2. Educating the Market

Many UK consumers still don’t know what ‘bean-to-bar’ really means, which is why workshops like the one organised by Sophie are a great resource. Why is a 70g bar £5 or more? What’s the difference between that and supermarket chocolate? Educating consumers about origin, process, and flavour is essential but resource-intensive for makers.

The heart of bean to bar

As Sophie explains, direct trade with cacao farmers is at the heart of bean-to-bar ethics. But it’s complex: international logistics, customs regulations, and even political/economic instability in producing countries can disrupt supply and affect quality, so trusted, speciality traders are essential in helping bridge the distance.

As well as the high costs of raw materials, UK independent chocolate makers have to deal with import rules, food labelling requirements, and trading standards, which have all shifted post-Brexit.

As Sophie says, staying compliant without a legal department can feel like a full-time job for small makers. “Chocolate is more than just bean to bar - makers need to look beyond the 'chocolate bar', to gifting and celebrations that are premium occasions where the public seek special experiences and turn to the skills of a chocolatier for high-end gifts and couverture.”

The York Cocoa Works Academy is a full-on learning centre. Craft chocolate isn’t just for Valentine’s Day or Easter anymore. Gifting culture, foodie fandom, and self-treating habits create a steady demand for premium bars all year round.

And as many bean-to-bar producers are discovering, there’s room for growth in high-end retail and boutique gifting markets. The makers who succeed will be those who stay true to their roots while embracing smart growth, strong storytelling, and deeper consumer connection.

Sophie and York Cocoa Works have strong roots. The 'Manufactory', after all, was established seven years ago - in a city that practically invented the modern chocolate bar.

The new era of UK chocolate makers are growing and thriving as they diversify their ranges and customer base to keep up with demand. Check out other brands like Chocolate Tree, Chocolarder, Bullion, Duffy, Dormouse, Tosier & Neary Nogs - who are pushing the development of a new, independent chocolate making industry in the UK.

- Want to learn more about bean-to-bar chocolate? Visit York Cocoa Works and its academy https://www.yorkcocoahouse.co.uk/

- For more information on craft chocolate visit: https://cocoarunners.com/

- 'From Our Desk. To Yours. Daily.'

- Sign-up here for free and upgrade to an annual plan with a 35% discount