The trust factor runs through the company’s supply chain like an invisible thread connecting various stakeholders from farmers to clients and ultimately consumers, to a family-owned B4B brand established in 1906 that is now a leading supplier of premium and sustainable cocoa to the global chocolate industry.

During the 2024 main harvest season, I visited Luker’s operation and witnessed firsthand how the brand conducts its business with farmers, communities, and clients. Local trust is relationship-based and personal, involving a cocoa buyer or trader visiting farms at least annually to ensure quality and fair practices through direct engagement.

Because Luker has one of the shortest supply chains in the industry, it does not require third-party certification – though it is a registered B Corp. Its sustainability record can be traced back to the brand’s origin, and evidenced annually in its published sustainability reports.

Institutional trust in Luker’s supply chain assures clients and consumers that cocoa is ethically sourced. Increasingly, consumers are going beyond certification, placing their trust in companies with fully transparent and sustainable supply chains—this is where distributed trust becomes relevant.

‘Smarter cocoa farming’

Luker is ahead of the curve in ‘smarter cocoa farming,’ using digital tools including AI, drones, and satellite imagery to enable data-driven decisions and sustainable farming. Partners trust the transparency and immutability of the Luker Trace system, which enabled Luker to achieve 100% traceability from regional buyers and associations in 2024, with the goal of achieving full traceability to farm level by 2027.

Over the past decade, Luker has transformed from a relatively unknown South American brand into a sought-after global B4B chocolate supplier. Its products are in high demand across the UK, Europe, and North America.

My visit to Colombia revealed both scope and substance. One leg of the journey took me to Tumaco, also known as ‘The Pearl of the Pacific’, a coastal city once plagued by gang conflict but now central to Colombia’s cocoa-for-peace programme. Luker, alongside NGOs and government partners, is helping Afro-Colombian and Indigenous farmers transition to sustainable, high-quality cocoa.

Tumaco’s fertile soils and humid climate produce fine-flavoured cocoa with floral and fruity notes, prized in premium markets. Luker sources approximately 10% of Colombia’s total cocoa from this region, from about 3,000 producers, many part of its Chocolate Dream initiative.

Watch this short video of a trip along the River Chagui to buy cocoa beans

During a 40-minute boat ride across the bay, we stop and buy fish directly from the fishermen; some are even cooking fish on a stove at the back of their boat. We continue until we reach the river inlet, and as we motor upstream, Conrad’s novel, The Heart of Darkness, comes to mind.

The Boatman’s Call

Along the River Chagui traders purchase beans directly from farmers, shouting “I buy cocoa!” into the jungle silence. Transactions are made at current market prices—roughly $6.28/kg at the time of my visit.

During harvest season, the trader makes 27 stops to buy cocoa beans, making this trip every week.

There are approximately 3,000 cocoa producers in the Tumaco region, and many of them have been beneficiaries of Luker’s Chocolate Dream initiative. Its objective is to improve the living conditions of cocoa farming communities and contribute to the construction of lasting peace in the region.

We met Jose, a former illicit crop grower turned cocoa farmer. With 30 hectares, he now thrives through Luker’s Cocoa Masters programme – part of The Chocolate Dream – which rewards agricultural best practices and sustainable farming. Jose’s cocoa is fully traceable and EUDR-compliant—no small feat in remote terrain with limited connectivity.

Before leaving Tumaco, I visited Sara’s farm and a Luker-supported school and nursery. With a yield of 900 kg/ha, Sara can earn over $20,000 annually from two hectares over two annual harvest seasons. Together with other crops and additional income generated from The Chocolate Dream projects, she is not complaining.

These initiatives encourage the next generation to pursue cocoa farming as a sustainable and profitable path.

Casa Luker and Chocolate Dreams

Luker operates three manufacturing sites, with Casa Luker in Bogotá producing 39,000 tons annually, serving as the central hub. The facility runs 24/7, meets international standards, and conducts cadmium testing for export markets. It also serves as a centre for innovation, developing vegan-friendly products like Tiger Nut M!lk Chocolate.

Luker supports private-label clients with full-service capabilities—from bean sourcing to R&D. Its ability to guide brands through the bean-to-bar journey is central to its appeal.

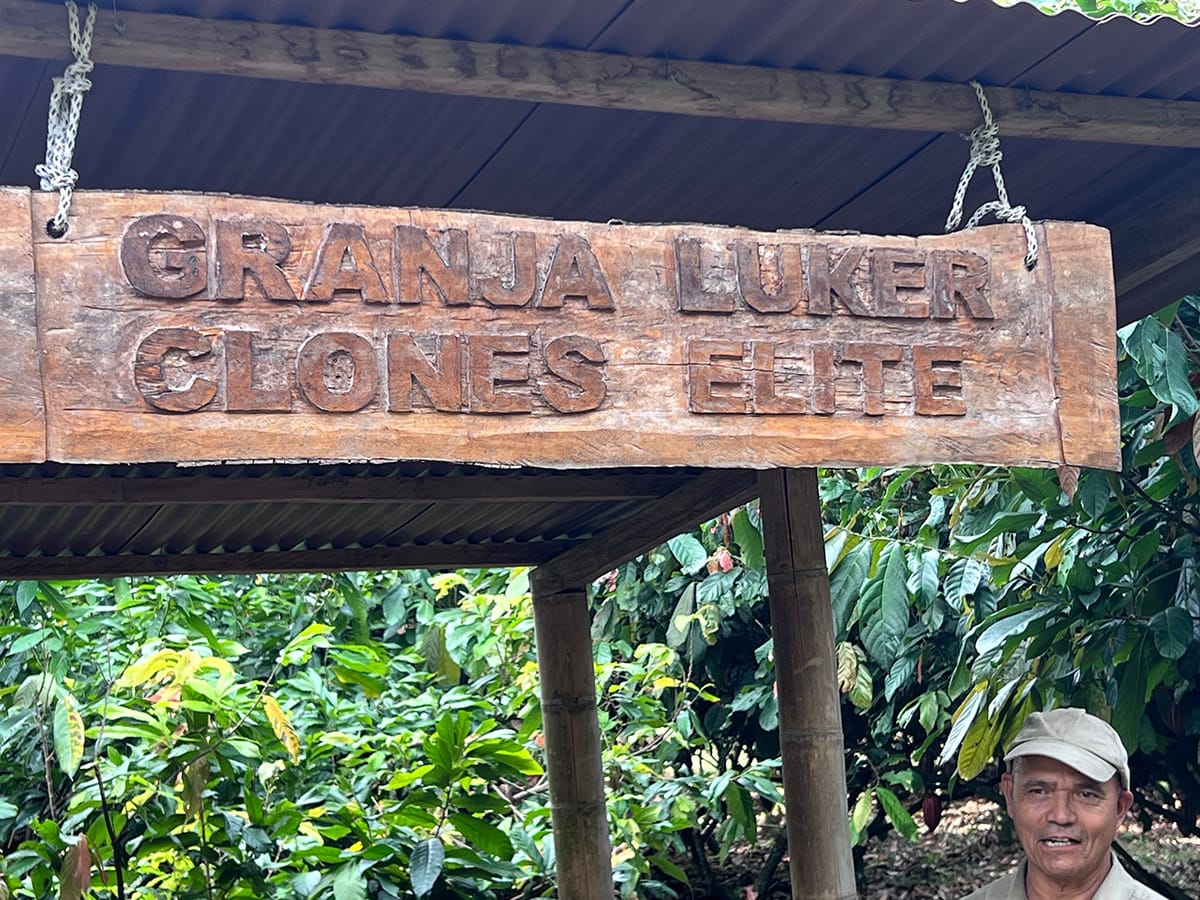

Granja Luker: The Cocoa Innovation Hub

For the past 60 years, Granja Luker in Palestina, Caldas, has trained over 32,000 stakeholders in cocoa innovation and sustainable agriculture. Julia Ocampo, VP of Cacao Sourcing & Sustainability, describes it as the birthplace of The Chocolate Dream—an initiative to triple yields, increase income, and foster gender equality and environmental stewardship.

Over a cup of cocoa (with melted cheese), she explains the significance of Granja Luker and how its legacy has transformed into The Chocolate Dream sustainability initiative.

“This is a place where we bring the farmers, but it's also a place where we create what we call the ‘anchor crop’ and a place where we can share all the knowledge from Ganja Luker with the community,” Ocampo says.

As with other cocoa-growing communities in different parts of the world, young people are turning their back on the farms and moving to the cities.

Ocampo explains that the challenge, not only for Luker but the chocolate industry in general, is how to bring young people back to the farms to secure supplies of beans for generations to come.

“The cocoa crops can have a life of 20 or 30 years. So if you learn how to manage the crop and the productivity, it's going to be a good business, and they can live well on the farm,” she says.

As explained in Tumaco, Luker collaborates with Fundación Luker, which has its own capital and supports initiatives in farming communities that promote education and entrepreneurship.

Granja Luker is a renowned centre for crop management and pioneering biodiversity. Images: CocoaRadar.com

Biodiversity

Biodiversity is another pillar. By helping farmers recognize the presence of wildlife and plant species.

“Biodiversity is the way that you really see, kind of the index of the environment that you're taking care of, so it is very easy to explain to the farmers that they are taking care of the biodiversity when they see the results of the different animals and species on their land.

“It’s easier than explaining how to take care of the soil or the water when you see that kind of natural biodiversity occurring,” Ocampo says.

The company also explores upcycling cocoa byproducts into flour, syrup, and even construction materials.

Combatting Crop Disease

Juan Pablo, Luker’s Chief Agricultural Researcher, is tackling threats like monilia (frosty pod rot) and Cherelle wilt. The former can reduce yields by up to 90% if unmanaged. Utilising satellite imaging and laboratory-based innovation, Luker is seeking both short-term and long-term solutions.

Cherelle wilt remains a mystery, with potentially devastating impacts. Granja Luker utilises data-driven research to solve such puzzles, including the development of experimental nurseries that produce more resilient cocoa tree varieties.

Luker’s commitment to intercropping, biodiversity, and yield improvement positions it as a leader in sustainable cocoa science - and the industry should take note of the ongoing work being undertaken at Granja Luker.

“We are proud of our results related to the implementation of recommended and proven practices that yield successful results with direct and immediate impact on productivity in the short term. This kind of research and application of new technologies will shape the future of cacao cultivation,” Pablo says.

Trust in Action

From riverboats in Tumaco to labs in Bogotá, Luker exemplifies how trust can be embedded in every link of the cocoa chain. The company's approach is more than a business model—it's a blueprint for sustainable, inclusive growth.

In Luker’s case, trust isn’t a slogan. It’s a strategy, a supply chain standard, and a social contract rolled into one. And in this corner of the world, cocoa’s future appears to be in very good hands.